trend:

Sustainable Marine Resources

year of foundation:

2014

founders:

Alessandro Taini Giorgio De Vitalis Andrea Pavoni

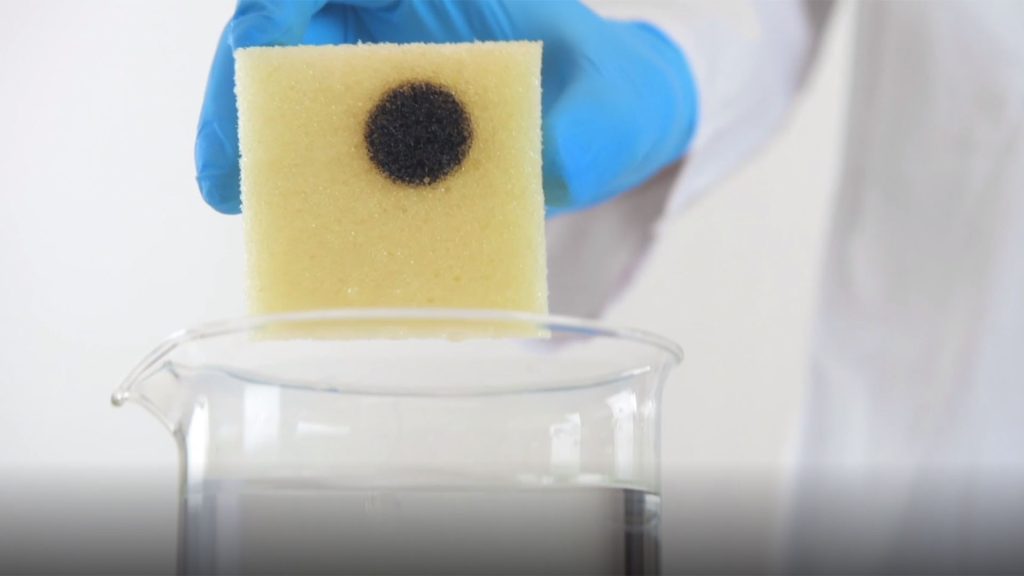

Test1 has developed and patented a flexible open-cell polyurethane foam specially treated, to make it suitable for cleaning up hydrocarbon spills on water and land.

This innovative material, called FoamFlex200, can absorb about 30 times its weight of any hydrocarbon and it can be reused more than 200 times, contributing significantly to the preservation of the environment.

meet the startup

The issue of hydrocarbon spills is far more serious than people think. According to the Istituto Superiore per la Protezione e la Ricerca Ambientale (Institute for Environmental Protection and Research), about 600,000 tonnes of hydrocarbons are spilled into the Mediterranean Sea each year, permanently affecting the ecosystem both environmentally and in terms of wildlife, while also causing damage to the industrial (especially fishing), tourist and commercial sectors.

What is the most effective way to clean hydrocarbon-contaminated water?

Test1 has developed and patented FoamFlex200, an oleophilic polyurethane foam sponge that can absorb hydrocarbons and derivatives up to thirty times its weight But not only that, unlike other ‘disposable’ products on the market, each sponge can be reused up to 200 times, proving effective regardless of the geographic area and conditions in which the spill occurs.

We had a chat about this with co-founder Alessandro Taiani.

How was Test1 established?

Test1 was founded in 2014 by Giorgio De Vitalis, Andrea Pavoni and myself, but the original idea has far more distant roots.

In the 1970s, hydrocarbons discharged by Montedison (Montecatini Edison S.p.A.) studded the Venetian lagoon with slicks that could be seen as far as St. Mark’s Square. Giuseppe Peroni, chemist at Montedison and also a friend of my father’s, was appointed by the then Mayor of Venice to find a solution to the problem.

In a report by the US Coast Guard, Peroni found that polyurethane could be specifically used to recover hydrocarbons in water. Yet his studies came to a halt before they could be implemented, partly because polyurethane turned out to be a very complex product from a chemical point of view and partly because Montedison was bought out and Peroni moved to the United States.

In 2014, Peroni randomly met my family and, together, we decided to resume the research that eventually led to Test1.

How long did it take you to patent FoamFlex200?

Two years of internal research and development were necessary to come up with the formula. In 2016, we moved on to a market analysis phase (structure, players, problems, needs), which led to a period of experimentation with different realities: organisations active in the oil industry, research laboratories and Italian and international universities.

These collaborations served to validate the product, testing the effectiveness of the material design, the application methods, as well as identifying possible problems and finding solutions.

The first off-lab experimentation took place in 2018, after storm Emma caused a number of boats to sink in Port Gran Tarajal in the Canary Islands, which resulted in a fuel spill. FoamFlex200 was used in the clean-up, allowing the recovery of 54 tonnes of hydrocarbons in just 2 days: 50 per cent of the spill compared to the 20 per cent usually recovered with more traditional technologies.

This first experience was followed by a growing number of uses in the oil sector (offshore and in-shore), in maritime transport and in yachting, in addition to the development of filtration systems in industrial contexts in Europe, Africa and the United States.

Acceleration paths have since begun: to date, Test1 has participated in 6-7 programmes across Italy and Europe. As of 2018, FoamFlex200 is a patented technology.

The first obvious association that comes to mind when thinking of a product that collects hydrocarbons is with large oil tankers spilling oil into the sea. Is there any other area and context of application?

Actually, that is just the tip of the iceberg, because spills happen every day, in every part of the world: whether it is people pumping petrol into their boats, ship decks cleaned with oil, refineries, pipeline spills, etc.

If you look at the figures available – for some countries it is impossible to obtain them – you find that the annual average of spills is more than double the tons of hydrocarbons that were leaked in the disaster in the Gulf of Mexico in 2010.

Suffice it to say that, in the Mediterranean alone, tens of thousands of tonnes of crude oil are spilled every year (UNEP United Nation Environment Programme – MAP Mediterranean Action Plan data).

We work in several market segments: oil sector (offshore and inshore), maritime transport, yachting, filtering systems in industrial contexts.

In some highly sensitive environments, such as in Sardinia, close to nature reserves or coral reefs, we are working on a contingency plan so that area managers are able – in the case of contamination – to intervene promptly to protect the water and safeguard the area.

We have also devised practical ‘Ocean cleaning kits’ that can also be used for small boats, such as 15-metre powerboats. They are useful for absorbing engine oil that accumulates together with water in the bilges and is dispersed into the sea when leaving port, when the bilges are opened to be emptied.

But Test1’s possible fields of application are not limited to the sea: we also intend to open up to the industrial sector, integrating FoamFlex200 into a line of filters that should be launched on the market in the next few months.

How is the acceleration process going?

We aim to expand our company with a view to service, not just product. In this sense, FAROS and the activities with its partners are of great help to us.

Furthermore, we have started a pilot project with Acciaierie d’Italia, a partner of the accelerator, in order to test our technology in new areas of application. In short, we are trying to maximise all the support given to us.

One day, who knows, we might end up with a sort of green technology hub for managing hydrocarbon pollution.